Precast Thermal Wall

The wall with integrated formwork and insulation

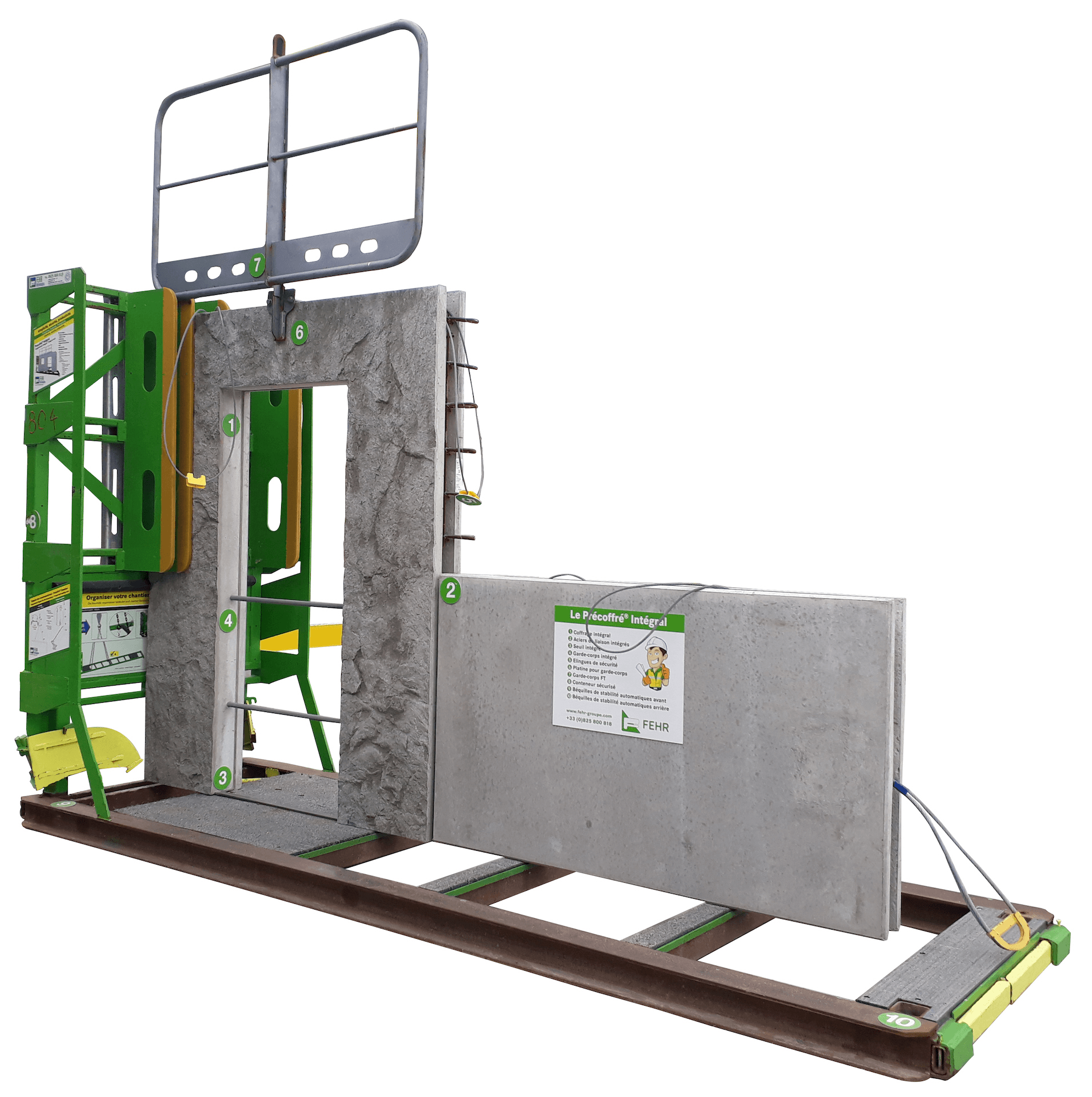

Precast Thermal Wall is a precast wall with integrated formwork made up of two fine reinforced concrete panels that are connected to each other and held apart by a system of connectors (composite connectors and load-bearing anchors), providing external wall insulation and a central space into which ready-mix concrete can be cast.

This made-to-order structural product is delivered just in time to your work sites, with all the reservations required.

| Technical Characteristics(according to current Technical Notice) | |

|---|---|

| Max dimensions | up to 12.34m x 3.80m* |

| Wall thickness | from 28 to 70 cm* |

| Wall panel thickness | 6 to 8 cm interior / 6 to 9.5 cm exterior |

| Insulation | 6 to 35 cm thick |

| Uwall | 0.471 to 0,063 W/m2.K |

| Concrete class | min. C 40/50 |

| Average weight | approx. 350 kg/m2 |

| Concrete exposure classes | XF1; XA3 |

| Fire resistance | 2H – REI 120 |

| Seismic zone | Yes |

Précoffré® Thermique, or thermal precast, provides thermal insulation, with insulation on the outside, thus eliminating thermal bridges at slab connections

Its Umur performance varies according to project requirements, up to 0,063 W/m2.K.

A structural product made to measure (up to 12.34m x 3.80m), it integrates all reservations and combines multiple advantages: winter/summer thermal comfort, acoustic comfort, elimination of thermal bridges, insulation protection, air and watertightness, implementation in seismic zones, use in infrastructure, use without building height restrictions and fireproofing up to 2H.

A structural product made to measure (up to 12.34m x 3.80m), it integrates all reservations and combines multiple advantages: winter/summer thermal comfort, acoustic comfort, elimination of thermal bridges, insulation protection, air and watertightness, implementation in seismic zones, use in infrastructure, use without building height restrictions and fireproofing up to 2H.

Schematic diagram

Areas of use

Low-carbon concrete formulation:

Environment

Environmental impact of Precast WallEx-works

Some examples of constructions using the Precast Thermal wall

All our achievements

A precast wall for every construction project

Need insulation? Opt for Thermal. Combine exceptional technology and finishing with Architectural. Gain 44% productivity with Integral, the only precast wall that promises ease of installation, while optimising safety and performance on site.

Contact us!

A question about our products ? Do you want to contact our design office to study your project? Do not hesitate, we are available via chat, phone or email

Contact