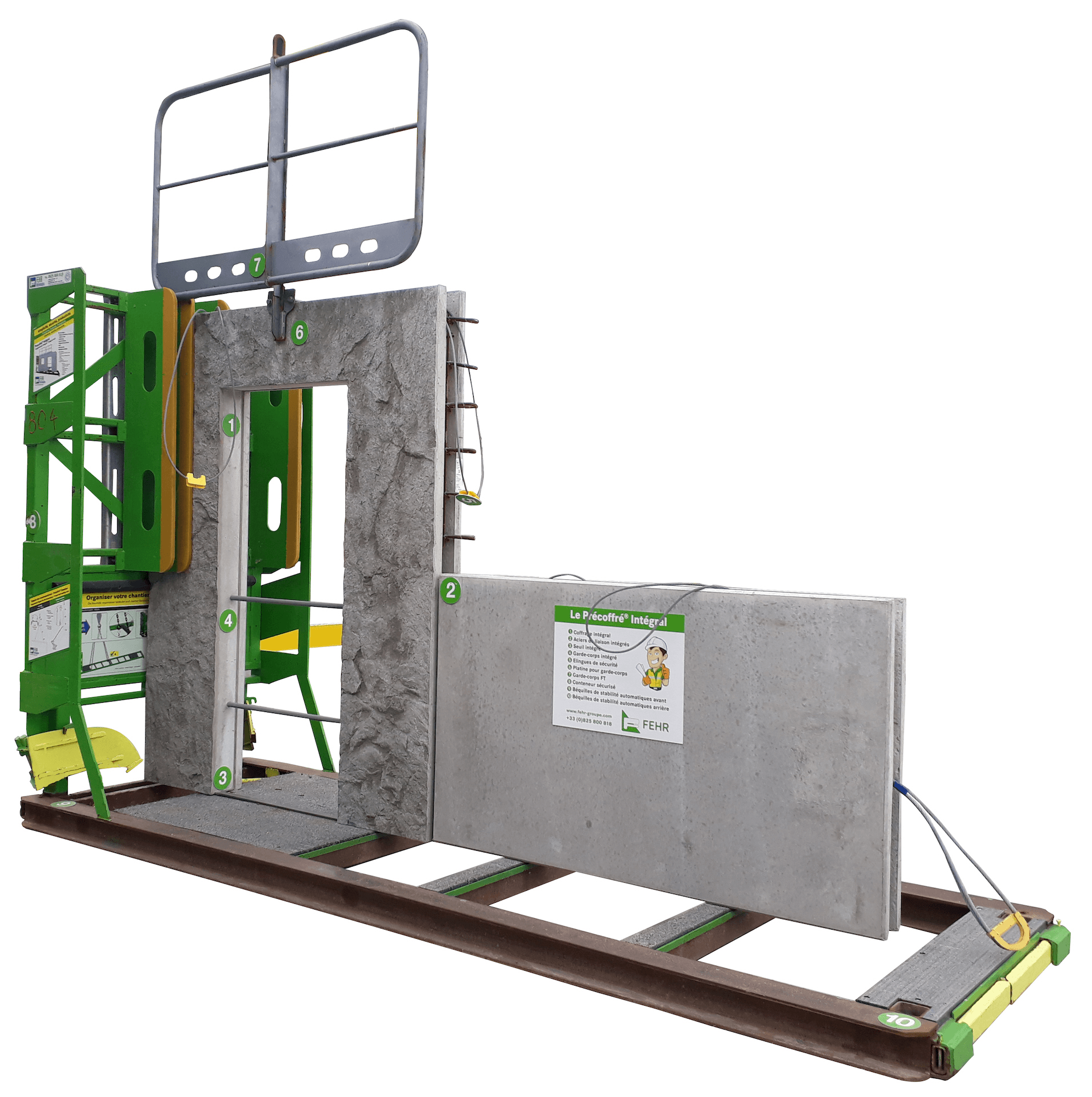

Precast Wall

Integrated formwork wall

Precast Classic Wall is a precast wall with integrated formwork made up of two fine reinforced concrete panels that are connected to each other and held apart by metal stiffeners, and a central space into which ready-mix concrete can be cast.

This made-to-order structural product is delivered just in time to your work sites, with all the reservations required.

| Technical characteristics(according to current Technical Notice) | |

|---|---|

| Maximum dimensions | up to 12.34m x 3.80m* |

| Wall thickness | 16 to 50 cm |

| Wall panel thickness | 4.5 to 7.5 cm |

| Concrete class | min. C 40/50 |

| Average weight | 280 to 350kg/m2 |

| Concrete exposure class | XF1; XA3 |

| Fire resistance | 2h - 4h |

| Seismic zone | Yes |

Schematic diagram

Fields of application

Excellence in Construction

Key Advantages of Our Prefabricated Solutions

Explore our range of prefabricated solutions that epitomize industrial-grade quality and adaptability. Each feature is meticulously designed to ensure enhanced site efficiency, safety, and environmental sustainability, all while offering aesthetically pleasing and durable construction solutions.

- Quality

- Custom-Made

- Adaptable

- Ease of Use

- Site Management

- Efficiency

- Safety

- Aesthetics

- Eco-Friendly

- Low Maintenance

- Durability

- Protection

Examples of constructions featuring the Classic precast wall

all our achievements

%20-%20Saint-Raphael.jpg)

%20-%20Boulogne-sur-Mer.jpg)

Low-carbon concrete formulation:

Environment

Environmental impact of Precast WallEx-works

A precast wall for every construction project

Need insulation? Opt for Thermal. Combine exceptional technology and finishing with Architectural. Gain 44% productivity with Integral, the only precast wall that promises ease of installation, while optimising safety and performance on site.

Contact us!

A question about our products ? Do you want to contact our design office to study your project? Do not hesitate, we are available via chat, phone or email

Contact