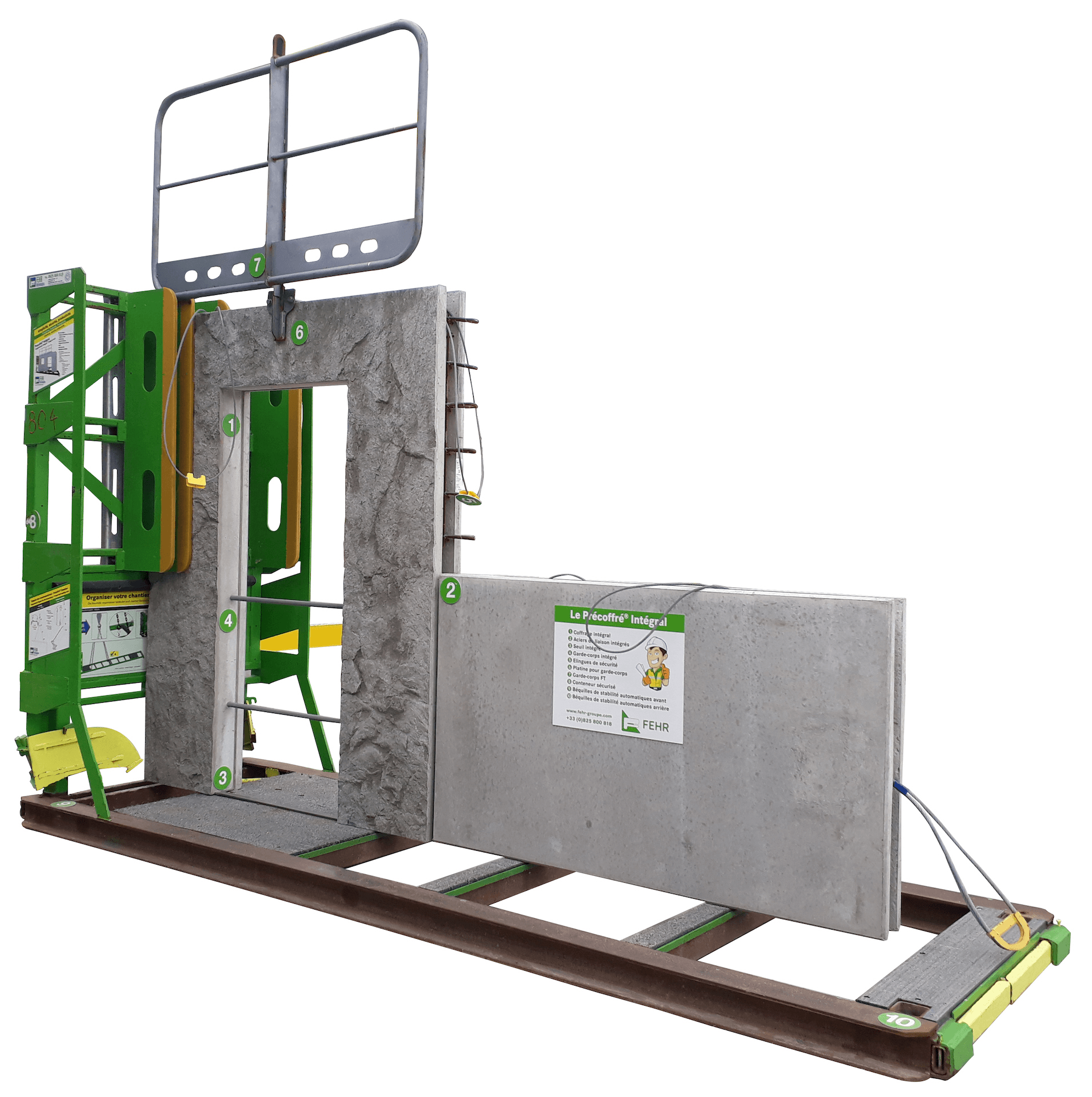

Precast Wall and its equipment

For a 100% safe wall

- Integrated formwork

- Integrated steel tie bars

- Integrated sill

- Integrated guard rail

- Safety slings

- Fastening plate for guard rail

- Fehr guard rail

- Secure container

- Integrated openings

- Automatic stabilising legs

Classic

| Max dimensions | up to 12.34m x 3.80m* |

| Wall thickness | 16 to 50 cm |

| Wall panel thickness | 4.5 to 7.5 cm |

| Concrete class | min. C 40/50 |

| Average weightn | 280 to 350 kg/m2 |

| Concrete exposure classes | XF1; XA3 |

| Fire resistance | 2H - 4H |

| Seismic zone | Yes |

Thermal

| Max dimensions | up to 12.34m x 3.80m* |

| Wall thickness | from 28 to 50 cm* |

| Wall panel thickness | 6 to 8 cm interior / 6 to 9.5 cm exterior |

| Insulation | 6 to 20 cm thick |

| Uwall | 0.471 to 0.11 W/m2.K |

| Concrete class | min. C 40/50 |

| Average weight | approx. 350 kg/m2 |

| Concrete exposure classes | XF1; XA3 |

| Fire resistance | 2h |

| Seismic zone | Yes |

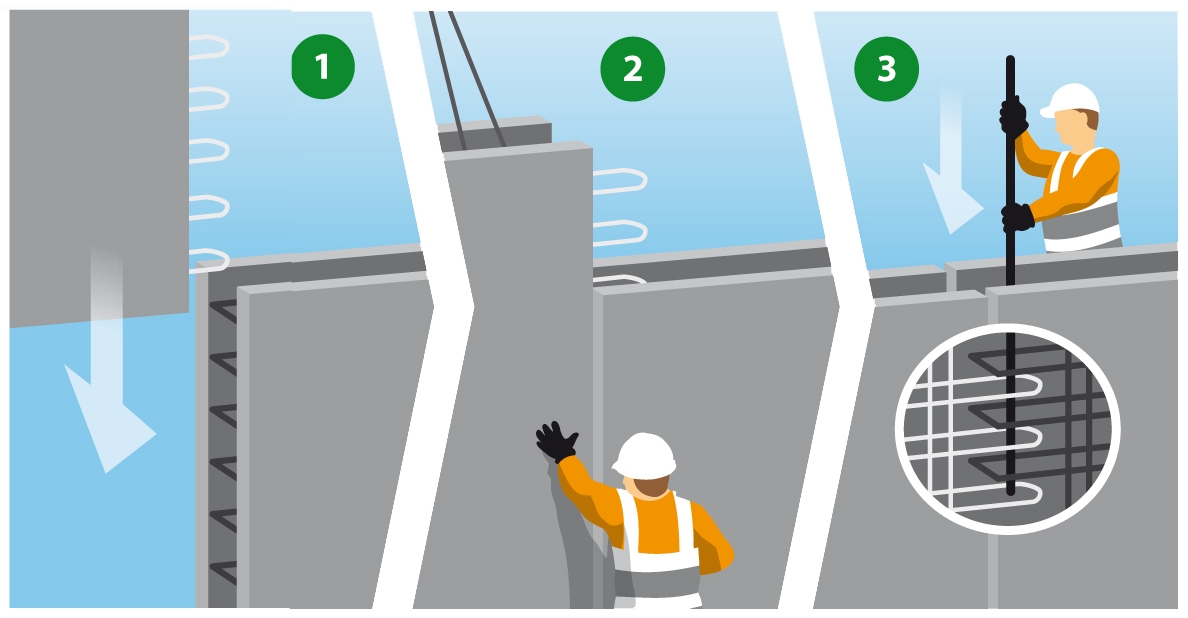

44% more productivity with less strenuous work

Factory concreted openings do away with all the restrictions imposed by wooden formwork that needs to be removed on the site: arduousness, scraps, cost of removal and recycling

Integrated steel tie bars make the work easier, since there is no longer any need to lift heavy reinforcing bars

Factory integrated sills save valuable time, because no reinforcing transoms need to be cut on site.

Concreted openings Integrated sill

- Time saving

- Simple finishing required

- No risk of fallsOpening of the breast wall for concreting

- No need to cut reinforcing transoms

- No removal of concrete sil

Integrated steel tie bars

- No handling to place reinforcing bars: no more arduous work, no more risk of falling from heights

- No rebar stock to manage on the construction site

- No space taken up by the rebar on the site: limitation of risks of falling on the same level

- Heightened safety and productivity

- No risk of cuts when handling the reinforcing bars

Low-carbon concrete formulation:

Environment

Environmental impact of Precast WallEx-works

A precast wall for every construction project

Need insulation? Opt for Thermal. Combine exceptional technology and finishing with Architectural. Gain 44% productivity with Integral, the only precast wall that promises ease of installation, while optimising safety and performance on site.

Contact us!

A question about our products ? Do you want to contact our design office to study your project? Do not hesitate, we are available via chat, phone or email

Contact