our environmental commitment

The planet: the priority from which all others flow

at a time of great climatic upheaval and unsustainable demands on the natural world, for us, protecting the environment through responsible construction is far more than a "simple" commitment: it’s an obvious obligation.

Because the living world is the basis of all things, the FEHR Group refuses to put profit before environmental impact, and is already working to construct the world of tomorrow – the “post-carbon” era..

As an environmental actor, the FEHR group places durable construction at the heart of its strategy.

- use of recycled aggregates and low environmental impact concretes.

- reduction of emissions and revaluation of waste

- systematic prioritisation of low-carbon materials

- manufacturing exclusively through internal channels

- supply logistics by rail or waterway

- reduction of distribution networks and energy consumption kept to a strict minimum.

a long ecological history

An Alsation family firm built on strong values, operating for more than fifty years at the border of France and Germany, FEHR has always held a strong moral stance on the environmental responsibilities of the construction industry.

In this region, where our natural heritage has remained largely intact, FEHR was born out of a dual desire: to offer sustainable construction that does not sacrifice reliability for environmental respect, and to remove the necessity of choosing between performance and responsibility.

Today more than ever, our company is proud to stand by its primary commitment: to respond to new ecological challenges through technological progress. The FEHR Group comprises 785 people, 9 plants, 5 production sites and 1 state-of-the-art laboratory, all dedicated to the research and production of even cleaner, tougher and better performing concrete.

committed to efficiency

In accordance with our goal to prove that reducing our industry’s carbon footprint goes hand-in-hand with providing sustainable – and reliable – construction, we continue to explore all possible solutions that make it possible to offer low-carbon and eco-responsible buildings.

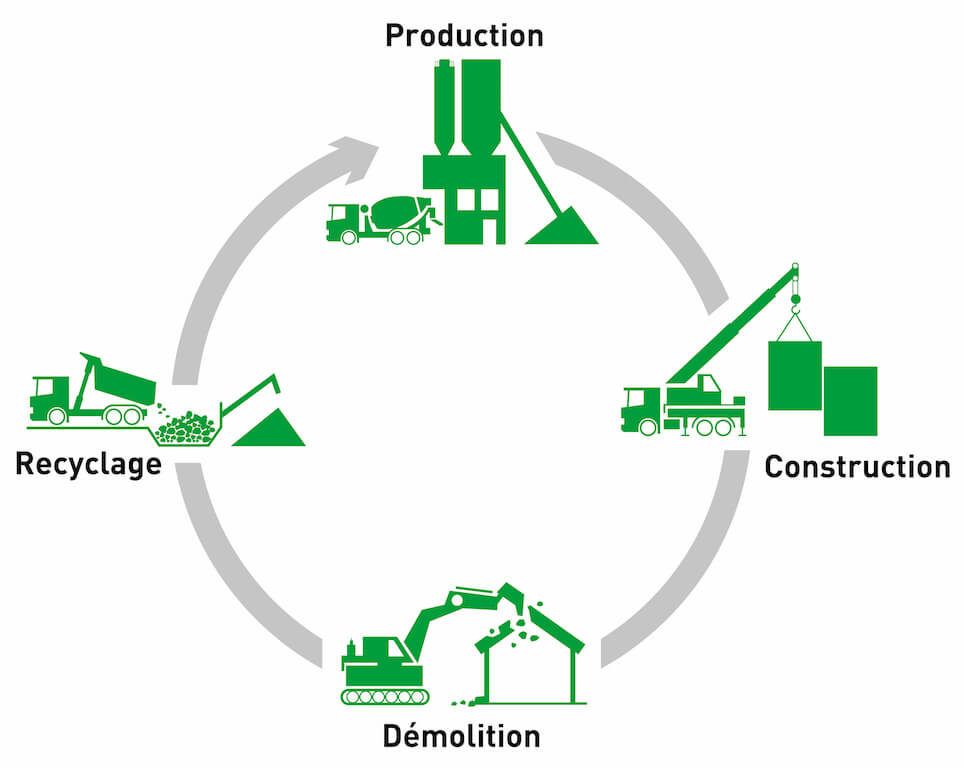

With this in mind, we strive to use recycled aggregate as far as possible in the composition of “heavy concrete”, for which compressive strength is the sole requirement. At the same time, we constantly motivate our research division to make maximum use of recycled concrete, without accepting any compromise on the safety and mechanical properties of the finished product.

We are furthermore committed to a 360-degree environmental approach, involving environmental management on our sites, in our products and in our multimodal logistics.

Looking ahead to last longer

we don’t wait for future standards to be implemented to take action – on site, all our activities are already RE2020 compliant and meet the most stringent environmental requirements.

We have been limiting our greenhouse gas emissions for almost 60 years, having chosen from the outset to favor local distribution networks, transport via waterways and the use of locally produced materials. By using low environmental impact concrete and low carbon raw materials today, the Fehr Group maintains its efforts to reduce its energy needs and confirms its position on the market – at the forefront of the global efforts to reduce CO2 across the whole construction sector.

protection through management

By using non-polluting products, relying on a direct supply of raw materials and recycling our waste, we are able to limit our energy consumption: these three axes form the basis of our approach to product management.

Simultaneously, our strategy of establishing sites in proximity to major economic centers allows us to offer a local response to customer projects, thus further limiting the impacts of transport.

Items are delivered without packaging and containers are returnable. Our Precast wall solution further allows for the advance delivery of containers to your construction site: this can be planned outside peak traffic hours and Friday highway congestion, thus contributing to the decongestion of traffic routes.

Finally, our products do not require any formwork panels, nor release agent on site. Construction times are cut and common pollutants attributed to construction sites are reduced: fewer consumables, less noise and less dust for your agents and our employees.

As for our staff, they are trained and up-to-date on environmental management, as well as on how to manage emergency situations: environmental audits are systematically integrated into the planning of internal audits, and into our management reviews. We also stay abreast of all the latest legislation, in order to take appropriate action.

By setting ourselves the goal of further reducing our carbon footprint by 30% over the 2020-2030 period, by continuously reducing the volumes of waste we produce, by starting now to provide low-carbon cement formulas, by incorporating recycled aggregates and offering bio-based insulation, we hold true to our original commitment: to reconcile durable construction with improved environmental performance.

The living world is too precious to be sacrificed on the altar of competition – and further contributing to the uncontrolled pressure on our natural resources is out of the question. Controlling environmental risk is our central priority; it is a goal we are proud to serve.

Starting now.

The FEHR Group is a member of theFédération Française de la Construction Passive.