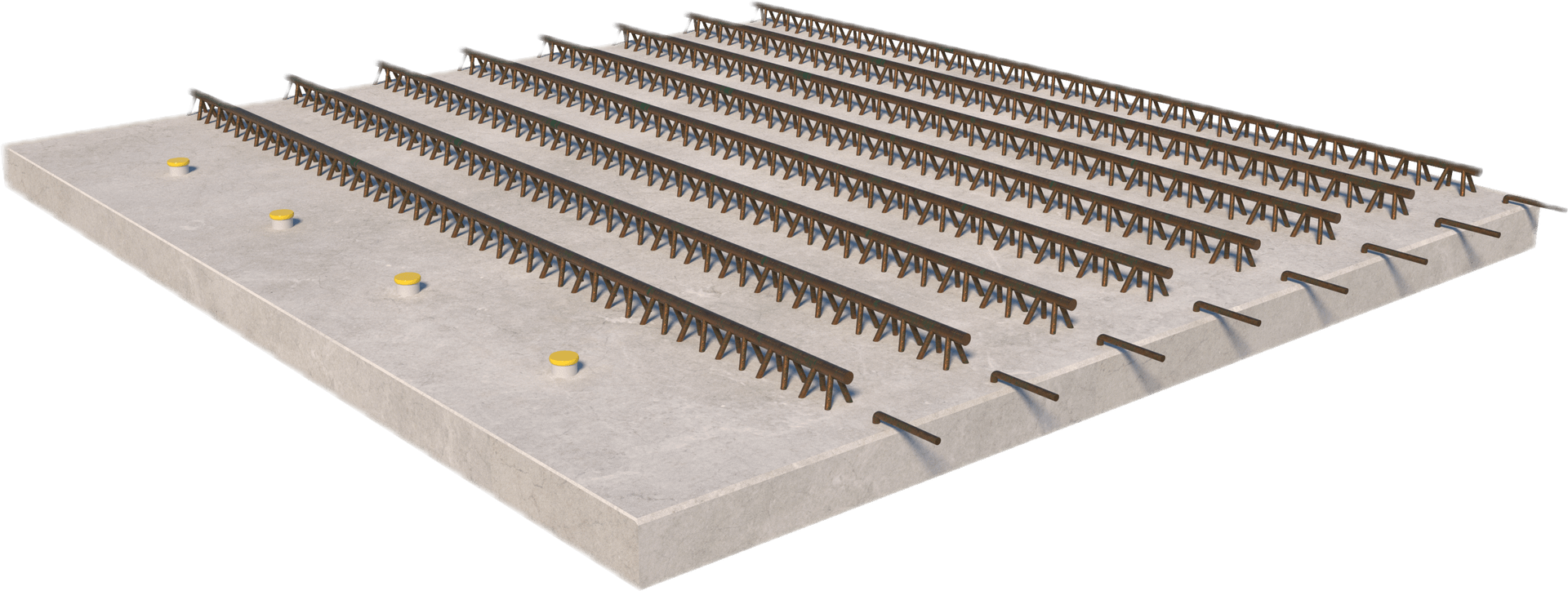

Precast slab: a concrete rock solid foundation

Formwork and floor strength

Precast slabs are vital for your building's structure, serving as formwork and ensuring floor strength, adapting to all architectural needs. FEHR's innovative precast slab, available in various thicknesses and customizable for any construction format, provides superior benefits over traditional prestressed concrete slabs. It's an essential ally for your building.

| Technical characteristics | |

|---|---|

| Length | 10 m |

| Width | standard width 2.5 m, possible up to 3.80 m |

| Thickness | from 5 to 8 cm |

| Concrete class | C 40/50 |

Application Areas

Why choose the FEHR precast slab?

Speed, quality, cost reduction, and safety

- Speed of construction: custom-made in the factory with standard widths of 2.50m and 3.00m, extendable up to 3.80m, installation of the precast slab is faster on-site, accelerating the overall construction process

- Reduction in labor costs and construction time

- Guaranteed industrial quality and uniformity

- Design flexibility: the precast slab can be manufactured to precise specifications and in a variety of shapes and sizes, providing great design flexibility for engineers and architects. It can be tailored to the specific needs of each project

- Reduction of risks on site: by reducing the time spent on site and minimizing complex construction activities, the precast slab helps reduce risks while also reducing waste on site

- Guaranteed mechanical, acoustic, thermal performances, and fire resistance

Standard precast slab width 3.00m

Choosing our standard width 3.00m precast slab offers the following advantages on your construction site:

- Less crane time required

- Fewer precast slabs to install (compared to a 2.50m precast slab)

- Fewer precast slab joints to treat

- Fewer deliveries, unloading, and transports to manage (carbon footprint)

- Less shoring required (compared to standard shoring)

Practical case

On a 10,000m2 floor: every 6 precast slabs, a gain of 3m linear. You save:

- 1000 ml of joints to treat

- 200 precast slabs to install

- 13 trucks of precast slabs to unload

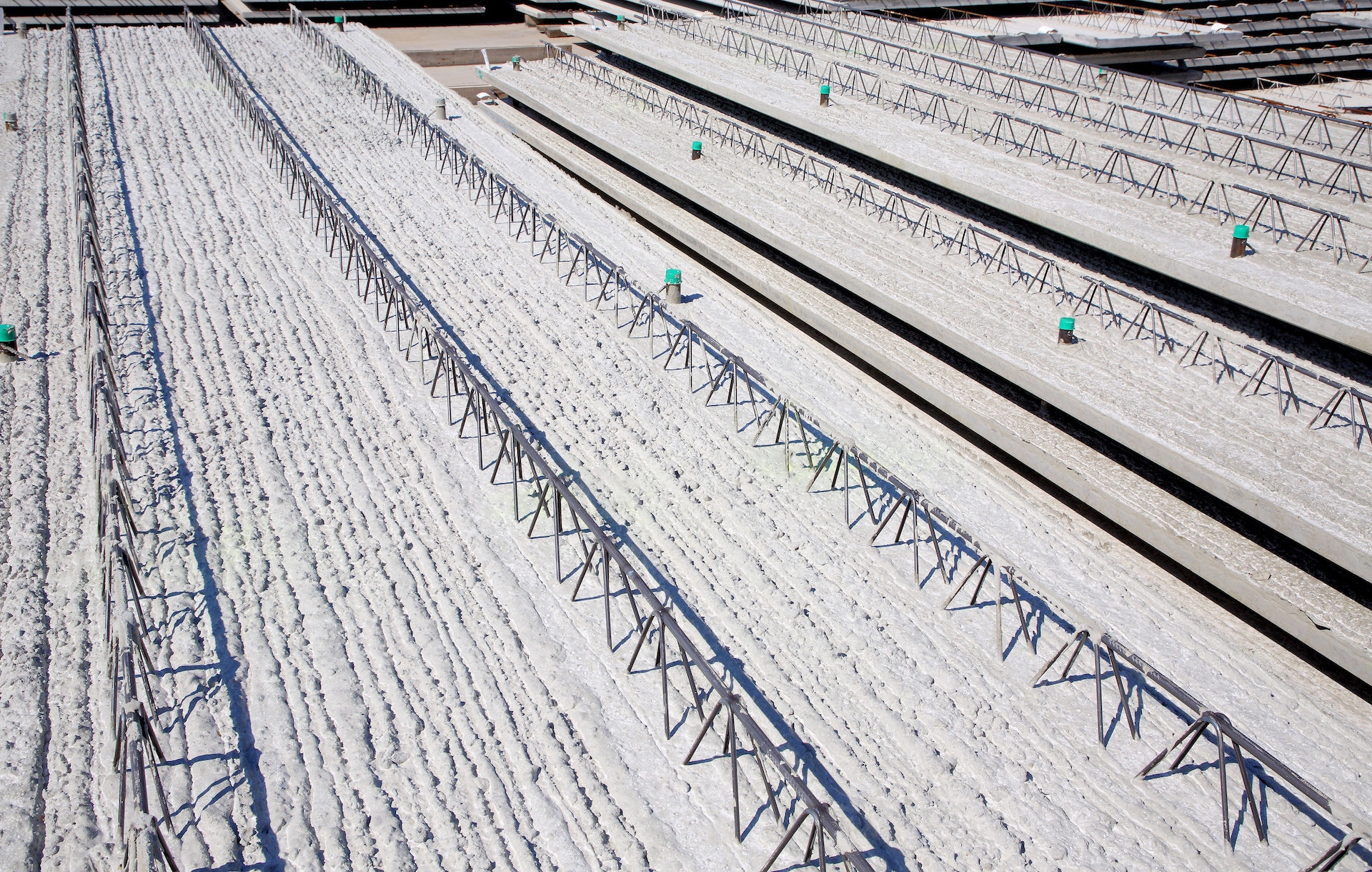

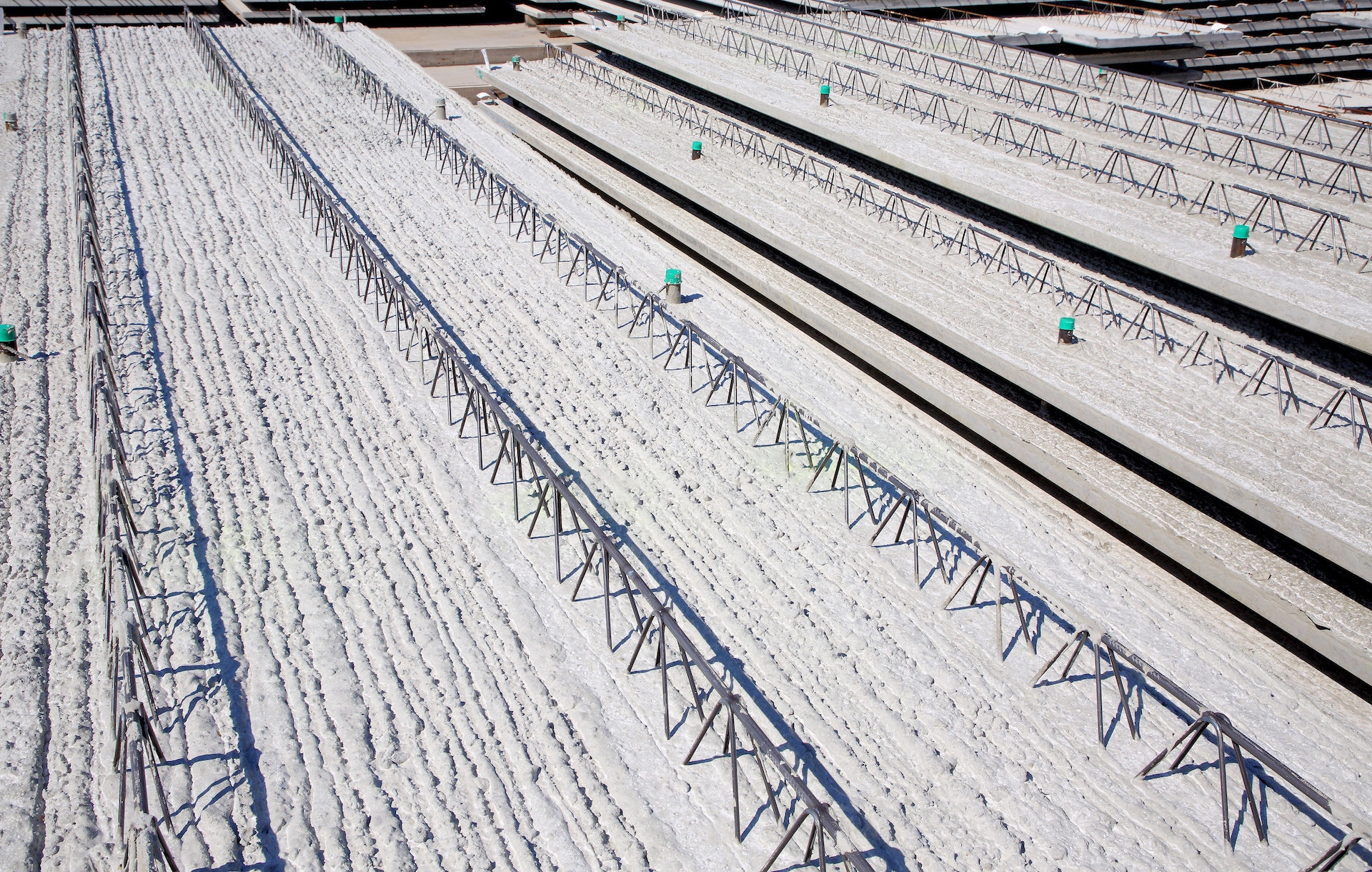

Examples of constructions featuring the FEHR precast slab

all our achievements

Contact us!

A question about our products ? Do you want to contact our design office to study your project? Do not hesitate, we are available via chat, phone or email

Contact