FEHR x MATERRUP: Cut the carbon footprint of your construction sites in half with non-calcined clay concrete!

FEHR Group and MATERRUP have joined forces to decarbonise construction as of now thanks to MCC1® circular, low-carbon cement.

This partnership is part of our joint commitment to achieve circular, decarbonised construction whilst offering quality products for the renovation and construction of the buildings of the future.

As of now, it is possible, thanks to the combination of MCC1® non-calcined clay concrete and Fehr Group's technical know-how, to provide relevant, cost-effective and attractive solutions with a high social and environmental value.

-50% CO2 on your construction sites

350 kg CO2/t compared to 752 kg CO2/t for traditional Portland cement

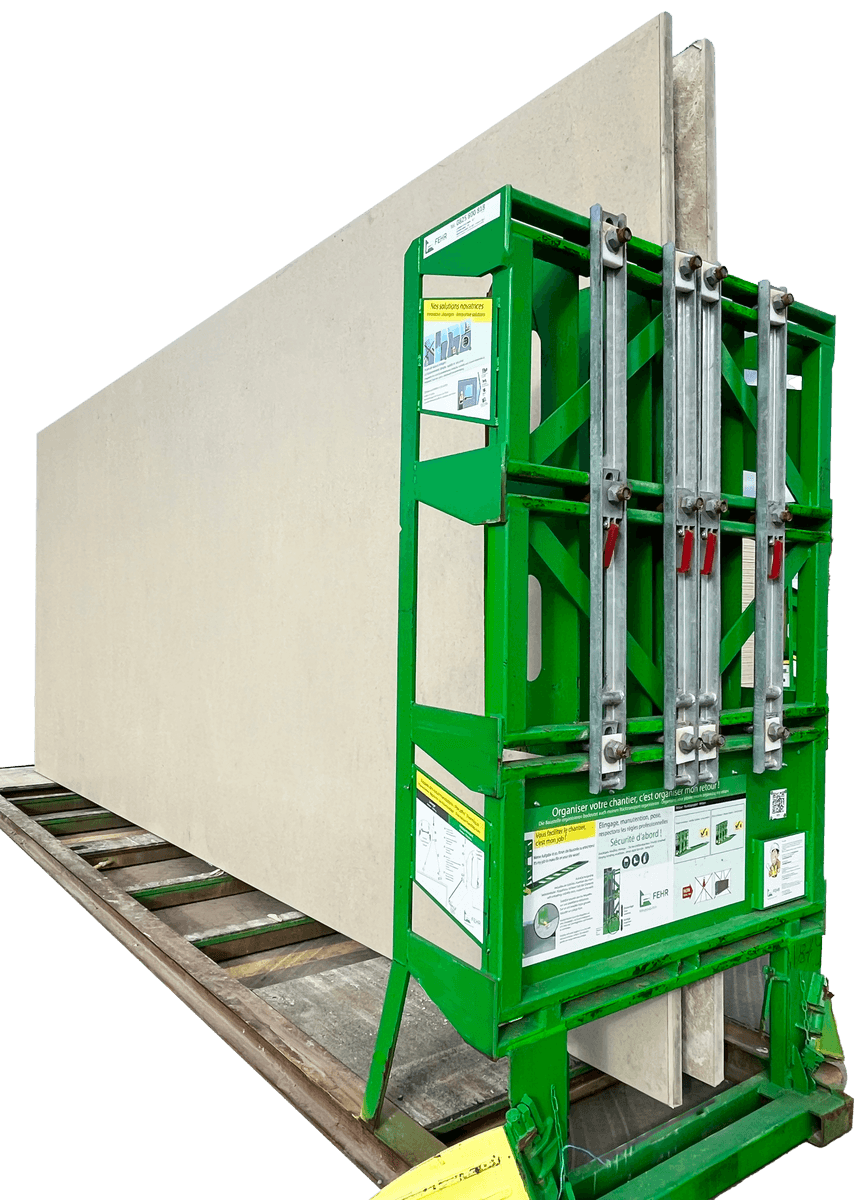

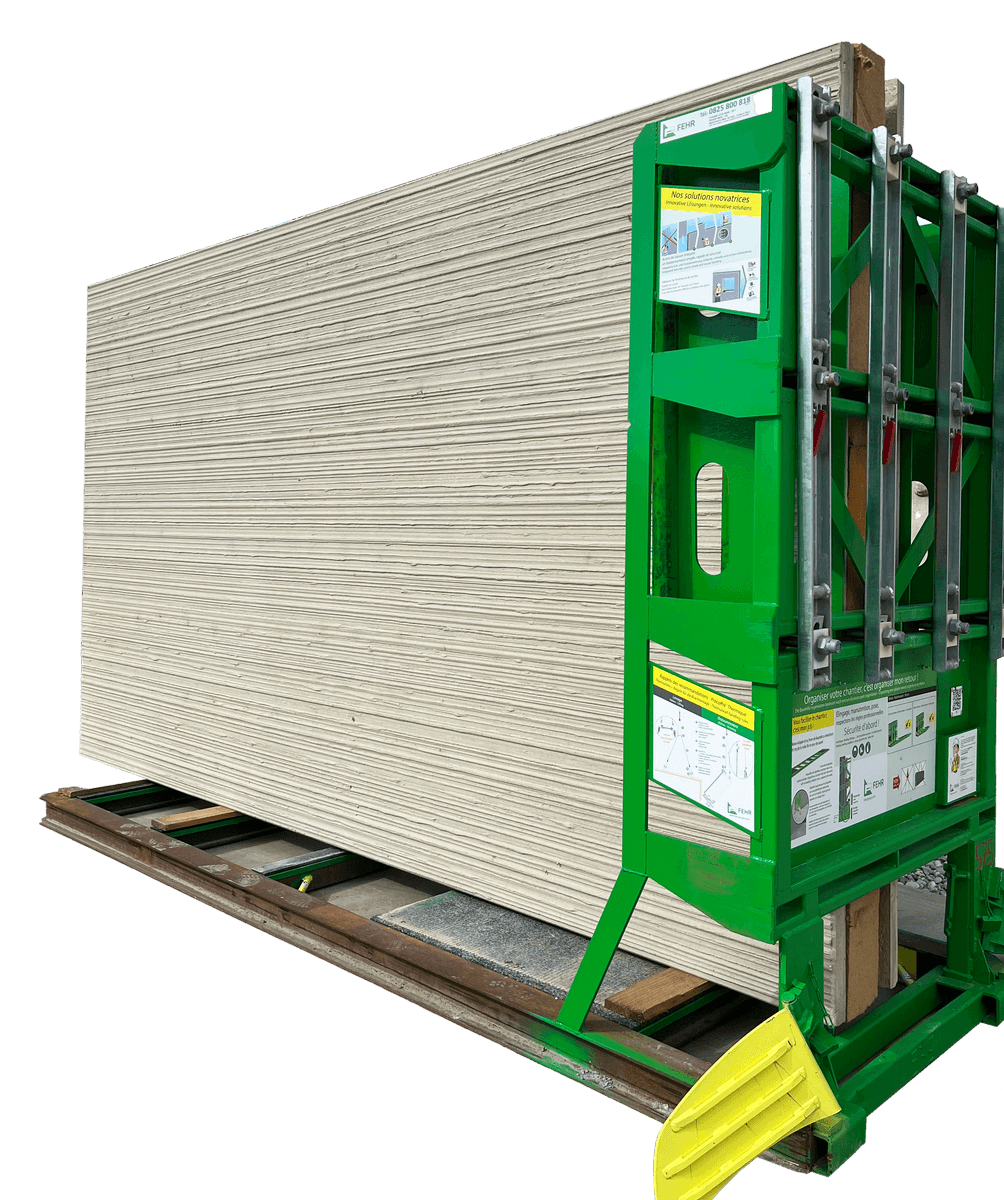

Prefabricated solutions

Precast wall

22.2

kg CO2eq/ m2 Materrup cement

40.2

kg CO2eq/ m2 CEM I cement

Precast thermal wall

51.4

kg CO2eq/ m2 Materrup cement

71.2

kg CO2eq/ m2 CEM I cement

Slab

12.3

kg CO2eq/ m2 Materrup cement

24

kg CO2eq/ m2 CEM I cement

Ready-mix concrete

For concrete slabs, foundations, pervious concrete. But also decorative concretes (terrazzo, deactivated, bush hammered, brush finish).

120

kg CO2eq/ m3 Materrup cement

262

kg CO2eq/ m3 CEM I cement

FEHR x MATERRUP: a partnership working to decarbonise construction

Low-carbon concrete

So what is Materrup's solution?

- 350 kg CO2/t compared to 752 kg CO2/t for traditional Portland cement

- 50% less CO2

Materrup's technology is an intrinsically and indisputably low-carbon cement made from non-calcined clay. This is an abundant raw material sourced from waste and reused. Materrup transforms locally recovered clay into a very high environmental value construction material for local use. The Crosslinked Clay Cement® technology developed by Materrup is patented, certified and covered by the decennial construction warranty.

Contact us!

A question about our products ? Do you want to contact our design office to study your project? Do not hesitate, we are available via chat, phone or email

Contact