1960: Albert Fehr

Albert Fehr, carpenter, started his own building firm.

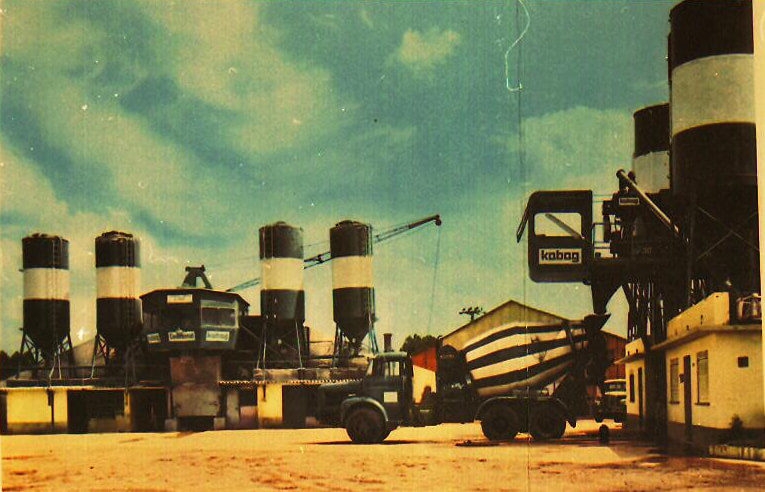

1968: 1st concrete mixing plant

Construction of the first concrete mixing plant. 8 more would follow, in Alsace and Lorraine.

1972: 1st precasting plant

Creation of the 1st precasting plant in Bischwiller in Alsace.

1988: First large-scale jobs with the Précoffré® product

Industrialisation of the precasting process at Bischwiller and first big jobs with the Précoffré® integrated-formwork wall product in Alsace.

2002: Industrial plant opened at Vernou

Industrialisation of the precasting process at Vernou-La Celle sur Seine and first big jobs with the Précoffré® integrated-formwork wall product.

2007: 3rd precasting plant

Construction of the third precasting plant in Châteauneuf-sur-Isère in the Drôme.

2008: Thermal Précoffré®

Précoffré® Thermique: the wall with integrated formwork and integrated insulation that guaranteed optimum safety with the containers and slings integrated with the Précoffré® wall.

2011: 4th factory, in Germany

Integration of a 4th factory in Wiesental in Germany.

2013: Précoffré® Intégral

The Précoffré® Intégral product, with its 10 patented solutions, facilitates installation and improves safety while optimising productivity, gaining 44% on the construction site.

2014: 5th factory, in Germany

Integration of a 5th factory based in Achern in Germany, specialising in Ultra High Performance Fibre-Reinforced Concrete elements.

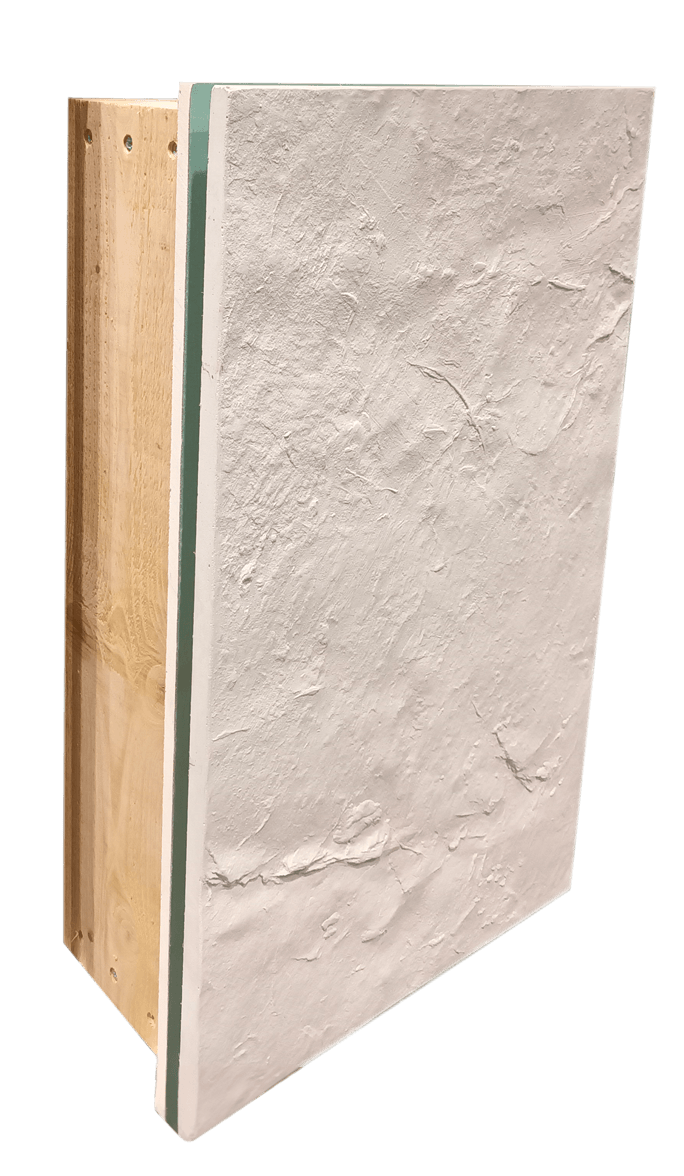

2015: FClad®

Launch of the FClad® Ultra High Performance Fibre-Reinforced Concrete cladding panel with Ductal® Inside.

2016: Improvement of the 3D FConcrete configurator

Refinement of the 3D configurator for FConcrete.

2018: FDriver App

Digitalisation of delivery notes via the FDriver app.

2019: Online BPE ordering

Launch of online ordering for Ready-Mix Concrete (BPE).

2020: Précoffré® TH Green low carbon

The first very low-carbon prefabricated wall, with bio-sourced insulation made from wood fibre.

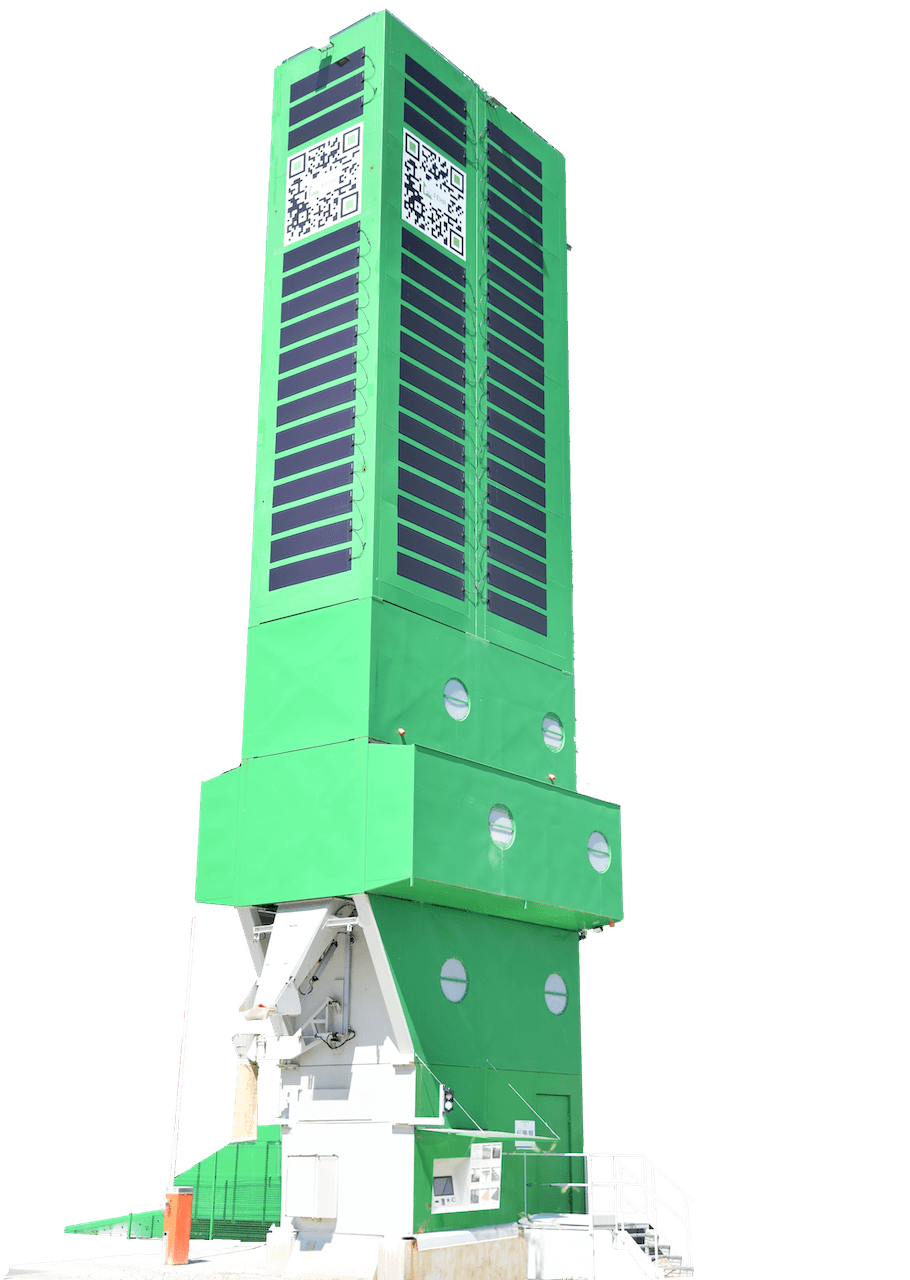

2021: Bétondrive

First autonomous distributor of ready-mix concrete.

2022: Raw earth concrete

Made from sand, gravel, earth, and water. Digitalisation of supplier invoices.

2023: FOBB Fehr Wood-Concrete Structure® Woodwall Ductal®

Wood-frame façade with integrated insulation and an exterior skin made of Ultra High-Performance Fibre-Reinforced Concrete.

2024: FEHR x Materrup Partnership

Halve the carbon footprint of your sites with Materrup's uncalcined clay concrete.